Inhoudsopgave

Understanding the Importance of Belt Cleaners

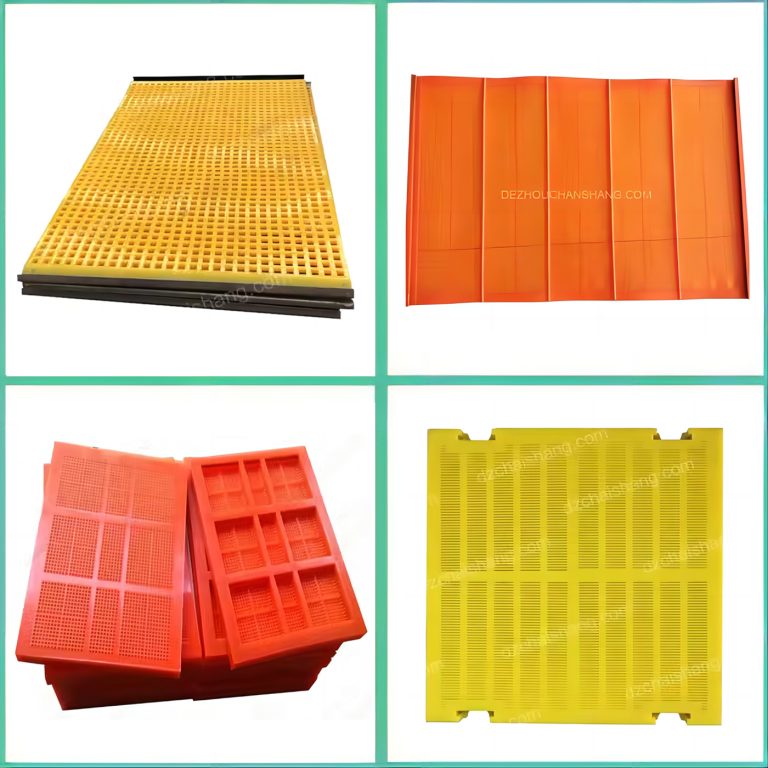

Belt cleaners play a crucial role in maintaining the efficiency of conveyor systems. They are designed to remove material that sticks to the belt after the discharge point, preventing buildup that can lead to various operational issues. By ensuring a clean belt surface, these cleaners help reduce wear and tear on the conveyor components, which can extend the system’s lifespan and enhance overall performance. When belts are not adequately cleaned, they can accumulate debris that affects the friction between the belt and the pulleys. This buildup can cause slippage, leading to reduced throughput and increased energy consumption. Additionally, a dirty belt may contribute to misalignment and other mechanical problems, necessitating more frequent maintenance and even unexpected breakdowns.

Selecting the Right Belt Cleaner

Choosing the appropriate belt cleaner is essential for maximizing conveyor efficiency. Different applications and materials require specific types of cleaners, so it’s important to assess the unique needs of your conveyor system. Factors such as belt speed, material type, and installation space should be considered when selecting a cleaner. For instance, primary belt cleaners are typically installed at the discharge point and are designed to tackle large amounts of carryback. Meanwhile, secondary belt cleaners provide additional cleaning and are positioned further down the conveyor. Selecting the right combination of these cleaners can significantly enhance cleaning effectiveness and reduce carryback.

Regular Maintenance and Monitoring

Regular maintenance and monitoring of belt cleaners are essential for sustaining their effectiveness. Over time, wear and tear can diminish the performance of the cleaners, making it necessary to inspect them periodically. By implementing a routine maintenance schedule, operators can identify potential issues before they escalate into costly repairs or downtime. Moreover, monitoring the performance of the belt cleaners can provide valuable insights into the overall efficiency of the conveyor system. Using sensors or tracking software can help identify patterns in carryback and wear rates, enabling operators to make informed adjustments. This proactive approach can lead to significant improvements in productivity and a reduction in operational costs, ensuring that the conveyor system runs smoothly and efficiently.