Table of Contents

Understanding Modular Polyurethane Screens

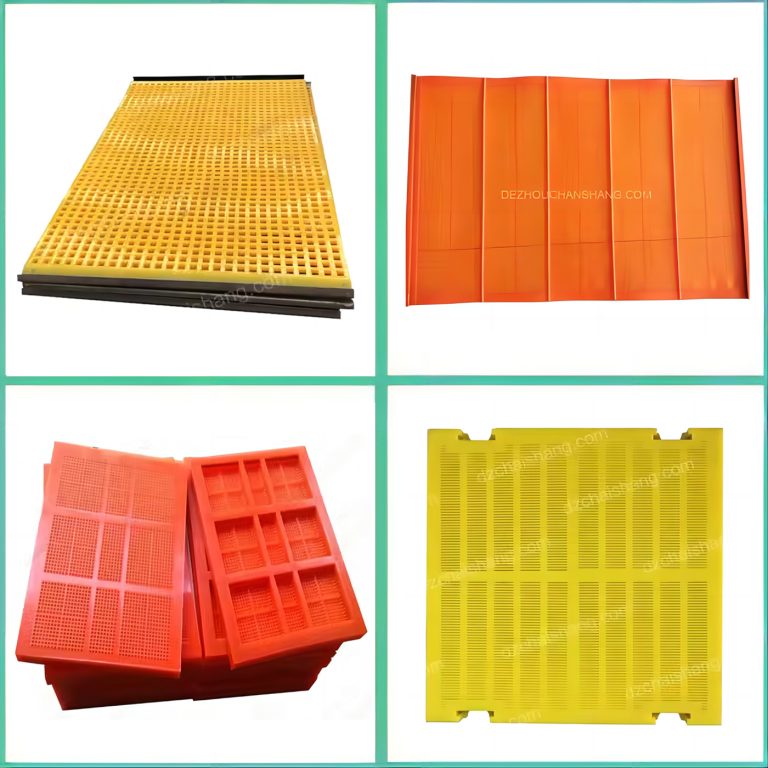

Modular polyurethane screens are essential components in mineral processing, designed to enhance the efficiency of separation processes. These screens feature a flexible design that allows for easy integration into existing systems. The modularity of these screens means they can be customized to fit various applications, making them suitable for different types of minerals and materials. One of the key advantages of modular polyurethane screens is their durability. Unlike traditional metal screens, polyurethane offers superior resistance to abrasion and wear, which is crucial in the harsh environments of mineral processing. This increased longevity translates to lower maintenance costs and reduced downtime, allowing operations to run more smoothly and efficiently. Furthermore, the unique properties of polyurethane allow for better screening performance. The screens can be engineered with specific apertures and surface textures to optimize the separation of materials. This adaptability helps in achieving higher recovery rates and improved product quality, making them a preferred choice for many mineral processing plants.

Benefits of Using Modular Screens in Mineral Processing

The use of modular polyurethane screens provides significant benefits over conventional screening methods. One major advantage is the ease of installation and replacement. The modular design allows for quick swaps, minimizing operational interruptions. This flexibility ensures that plants can maintain peak performance without extensive downtime typically associated with screen changes. Another benefit is the enhanced screening efficiency. Modular polyurethane screens can be designed with various openings and configurations tailored to specific mineral types. This customization helps in achieving effective stratification and reduces the amount of material that bypasses the screening process—resulting in a cleaner end product and higher yield. Moreover, the lightweight nature of polyurethane compared to traditional materials leads to reduced structural stress on screening equipment. This characteristic not only prolongs the life of the machinery but also contributes to energy savings, as less power is required to operate lighter screens. As a result, plants can enjoy both environmental and economic benefits from using modular polyurethane screens.

Installation and Maintenance Best Practices

Proper installation and maintenance are critical to maximizing the efficiency of modular polyurethane screens in mineral processing. When installing these screens, it is important to ensure that they are fitted securely within the frame to prevent gaps that can lead to material bypass. Regular inspections during the installation process can help identify any potential issues early on. Maintenance of the screens should include routine cleaning and checks for wear. Since polyurethane is resistant to many chemicals and solvents, cleaning can often be done using simple water or mild detergents. However, operators should be vigilant for signs of excessive wear or damage, as this could impact performance. Replacing worn-out sections promptly can prevent larger issues down the line. Additionally, training personnel on best practices for handling and maintaining modular screens can significantly enhance their lifespan. Operators should be educated on the specific characteristics of polyurethane and how to properly care for the screens to avoid unnecessary damage. By following these guidelines, mineral processing plants can fully leverage the benefits of modular polyurethane screens while ensuring optimal performance.